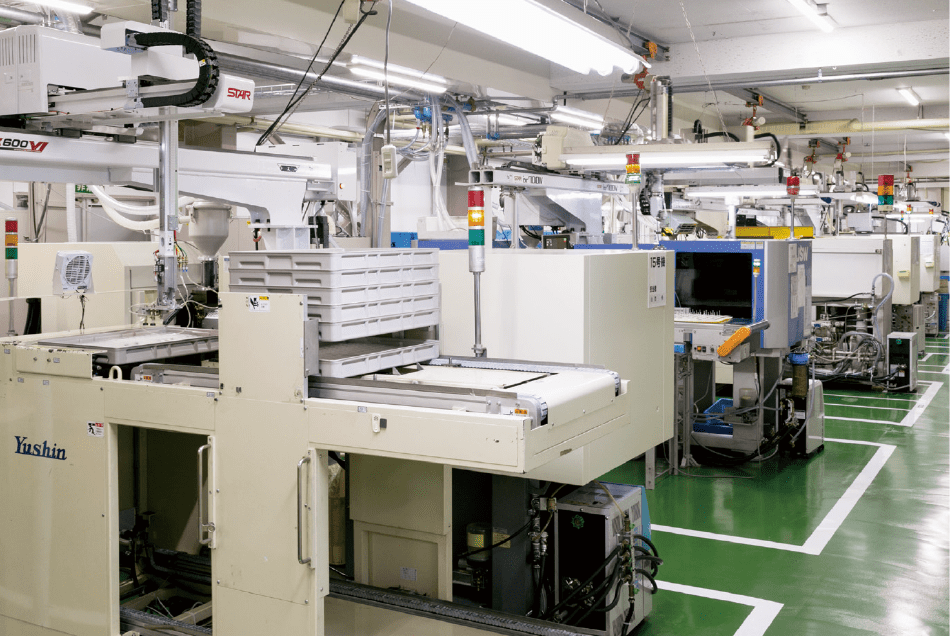

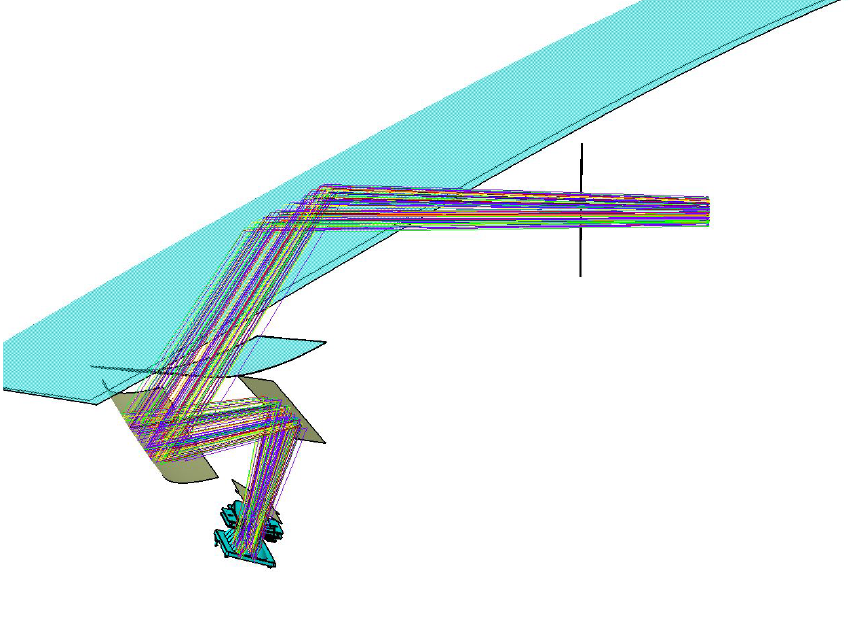

Integrated production that transcends corporate boundaries by leveraging the Group's strengths

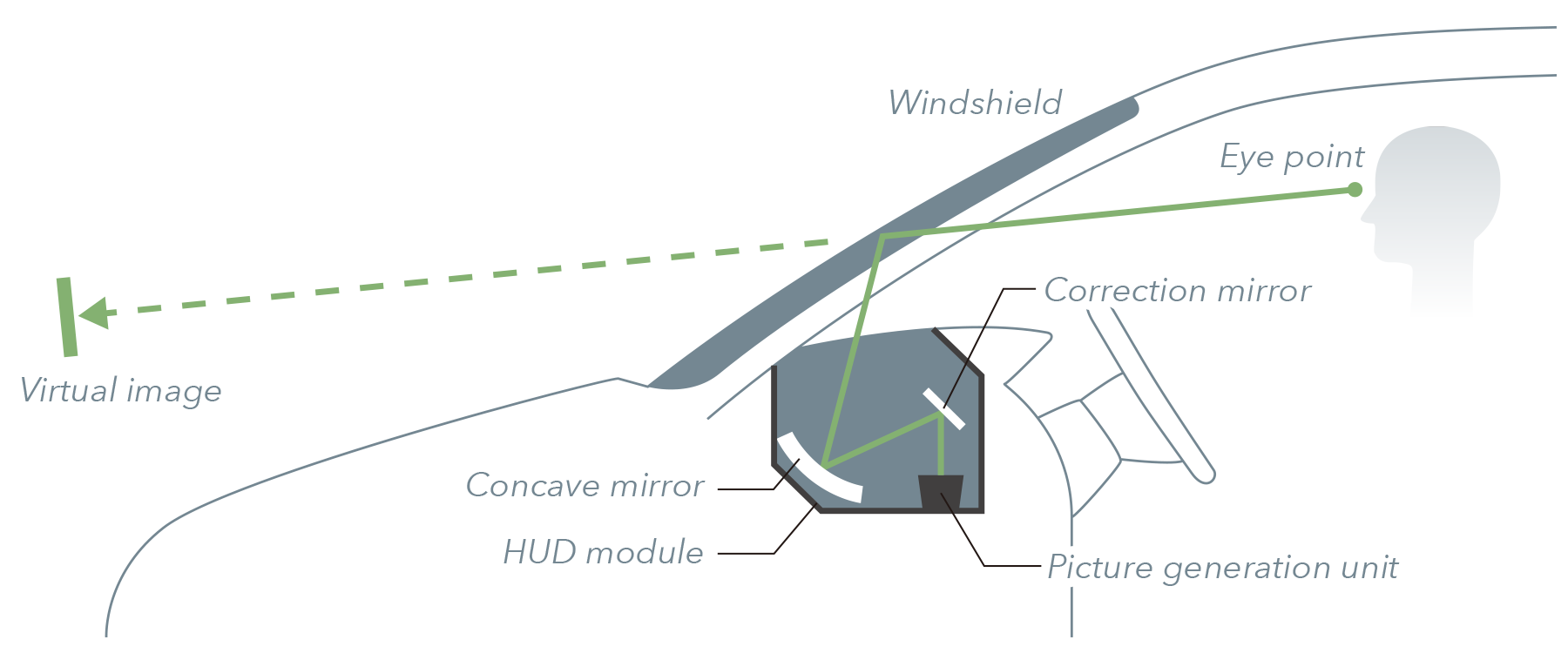

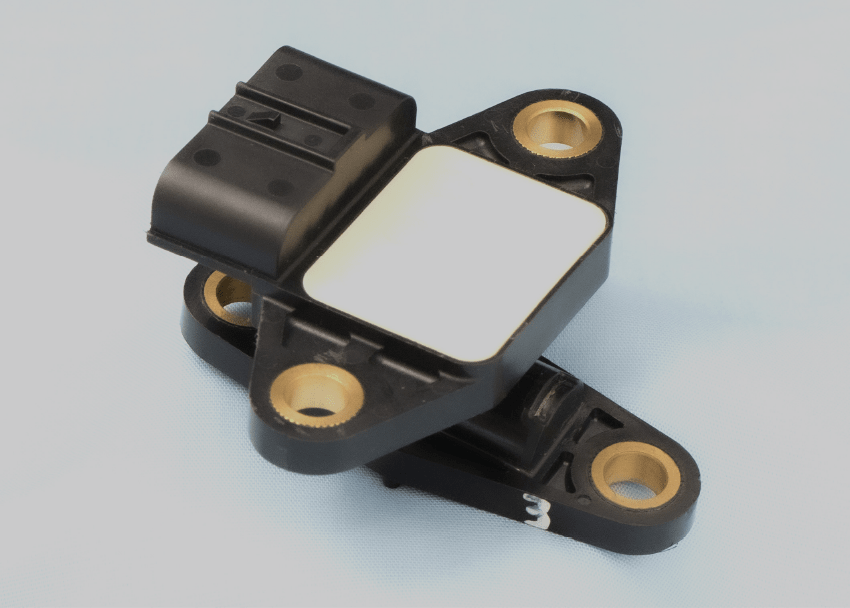

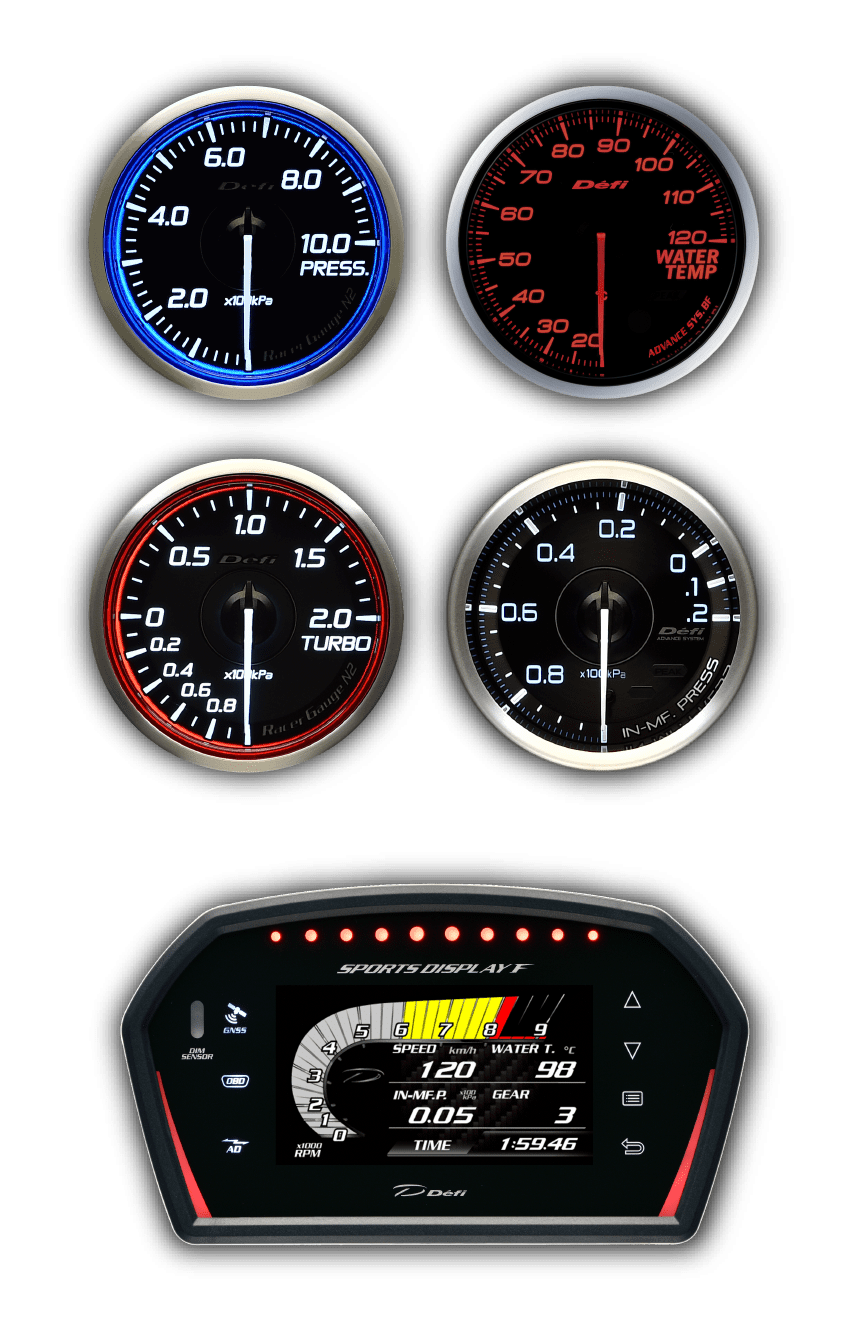

Nippon Seiki Group strength lies in its manufacturing technologies such as high-density mounting technology, precision molding, resin molding, printing, and an integrated development and production system that combines system, circuit, and exterior design and verification technologies. We are also enhancing our competitiveness by introducing in-house production of key components, such as movements that display guidelines that indicate speed, engine speed, and other factors, and printed circuit boards, which are indispensable for digital display.

![NIPPON SEIKI CO., LTD.[Plastic optics design]Various optical simulations can be used to design optical resin components that satisfy the required optical properties.|NS ADVANTECH CO., LTD.[Resin Molding/Resin Coloring/Assembly]Equipped with facilities from molding to inspection and packaging of optical components. Can be molded specifically for transparent thick lenses and micromachined lenses without foreign matter.|KYOEI ENGINEERING CO., LTD.[Microfabrication/Precision Machining/Mold]Making full use of various processing techniques to produce molds that meet requirements.It is also possible to make a prototype with the same accuracy as a molded product by directly scraping resin.](../img/business_ic_cont06_th.png)

![NIPPON SEIKI CO., LTD.Plastic optics design]Various optical simulations can be used to design optical resin components that satisfy the required optical properties.](../img/business_ic_cont06_th_sp02.png)

![NS ADVANTECH CO., LTD.[Resin Molding/Resin Coloring/Assembly]Equipped with facilities from molding to inspection and packaging of optical components. Can be molded specifically for transparent thick lenses and micromachined lenses without foreign matter.](../img/business_ic_cont06_th_sp03.png)

![KYOEI ENGINEERING CO., LTD.[Microfabrication/Precision Machining/Mold]Making full use of various processing techniques to produce molds that meet requirements.It is also possible to make a prototype with the same accuracy as a molded product by directly scraping resin.](../img/business_ic_cont06_th_sp04.png)